Vacuum Forming: An Overview

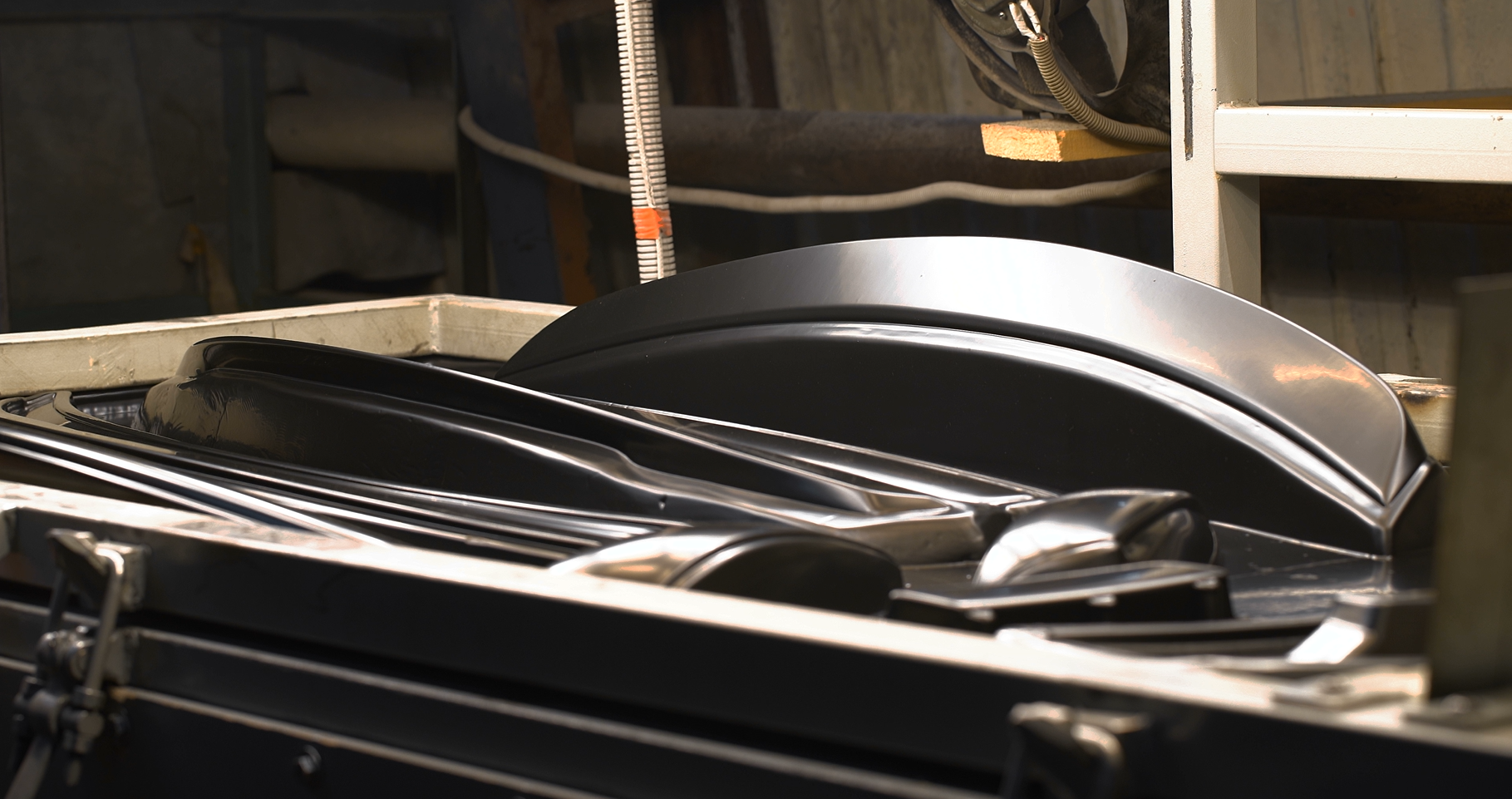

At PR Plast, we use vacuum forming to manufacture high-quality plastic parts. This method enables us to create complex three-dimensional shapes efficiently, precisely and offers numerous advantages.

What is Vacuum Forming?

Vacuum forming involves heating plastic sheets until they are soft and then shaping them over molds using a vacuum. We use this technique to create a wide range of products, including packaging, toys, car interiors, and medical instruments. This process is versatile and suitable for various applications.

How Does Vacuum Forming Work?

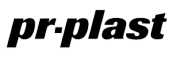

Heat: An aluminum mold is placed in the vacuum forming machine, and the plastic material is heated to a temperature between 170 and 210 degrees Celsius.

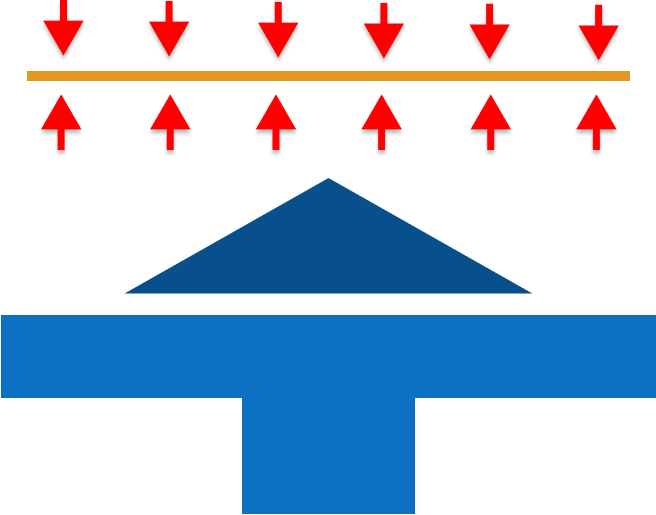

Air: The softened plastic is placed over the mold using compressed air.

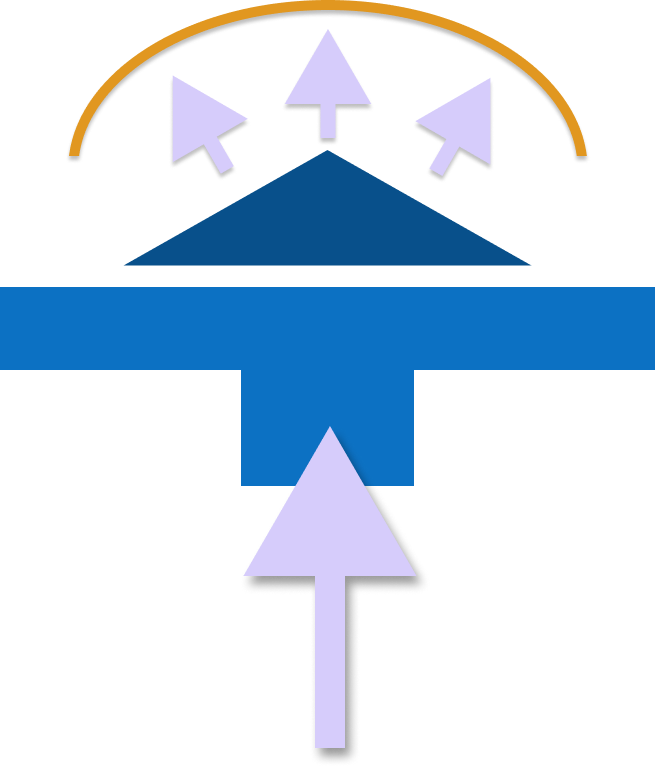

Vacuum: A vacuum is applied, forming the plastic over the mold, and then the plastic is cooled down.

Why is Vacuum Forming Effective?

Vacuum forming is highly effective for several reasons. Firstly, the technique is relatively simple and does not require specialized equipment, making it a cost-effective method for manufacturing products in smaller volumes.

Secondly, vacuum forming allows us to create highly detailed and complex shapes. The plastic sheet can form over a mold with a detailed design, allowing for a high degree of precision and accuracy. The method is efficient, enabling rapid production and flexibility in design adjustments.

Applications of Vacuum Forming

We utilize vacuum forming in various industries. For example, this technique is used in the automotive industry to create car interiors and other components, in the medical industry for manufacturing medical instruments, and in the packaging industry for creating packaging and display products. This versatility makes vacuum forming a preferred choice in many manufacturing processes.

Contact Us

If you have a project requiring vacuum forming or need more information about how this process can benefit your business, contact us today. Our team of experts is ready to assist you from concept to finished product, ensuring that your requirements are met with precision and efficiency.

For inquiries, please visit our contact page (PR Plast) . You can also reach out directly via email at info@prplast.se or call us at +46 63 57 55 50.

Get in touch to discuss your vacuum forming needs and discover how we can help bring your projects to life with our advanced technology and expert solutions.

Materials

At PR Plast, we use vacuum forming technology to create products from materials such as:

- ABS (Acrylonitrile Butadiene Styrene)

- PC (Polycarbonate)

- PP (Polypropylene)

- HDPE (High-Density Polyethylene)

- PETG (Polyethylene Terephthalate Glycol)

- PS (Polystyrene).

These materials are selected based on their properties, including durability, aesthetics, and function. They are suitable for industrial, construction, design, and architectural applications such as vehicle components, protective goggles, pipelines, displays, and insulation.

The materials we use in vacuum forming are carefully chosen to meet specific requirements for each application, ensuring that the end products are functional, durable, and meet the necessary standards for their intended use.

By leveraging the strengths of these materials and the vacuum forming process, we can deliver high-quality, precisely formed plastic parts that cater to a wide range of industrial and commercial needs.

Kontakta oss - skicka ett meddelande

Vi stöttar Östersunds FK